small, smaller, airbrush-nozzle

The tiny DICE needs a matching small nozzle. But I don't like the typical shape of an E3D-nozzle. And even less if it's about a nozzle-size of 0.2mm. When printing with such a small nozzle, you need to print slow and depending on the nozzle maybe hotter than usual.

EDIT: now available here

A big problem with small. hot and slow prints is the heatradiation of the hotend and nozzle itself. To get as little as possible heat into the print, the nozzle needs to be as long and pointy as possible. The longer the nozzle, the bigger the distance between heaterblock and the print. And the more pointy it is, the less heat radiation can affect the print. A nice side benefit: the cooling fan can blow better onto the print and "around" the nozzle.

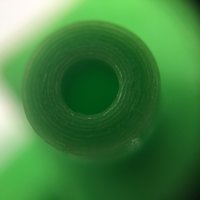

Conveniently, off-the-shelf airbrush-nozzles have exactly the shape I imagine for this task! Long, pointy and readily available in different small sizes. But these nozzles are soooo small! Look at the pictures! The tap is M1.7 - could become difficult to mount this somehow...

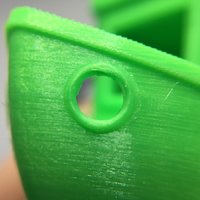

I needed some kind of adapter for this small thread and preferably it should fit into my E3D-V6. For this, I designed an adapter with a small footprint and a little tip, to increase the length even more.

The drawing can be downloaded here.

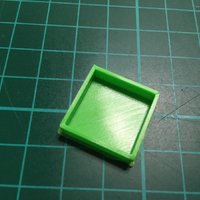

The first 2 tries with the new airbrush-nozzle looked like this. After the first ugly looking print, I reduced the flow by 10%, set 'coast at end' to zero and the second print was on spot!

I jumped into cold water and started a more pretentious print with 0.05mm Z:

This 18mm small dwarf is one of my favorites if I want to test small, compact and detailed prints. Now there is some sort of soft stringing. It does not look exactly like stringing. More like there is very little filament blown away, like candyfloss. Maybe the flow is still too high.

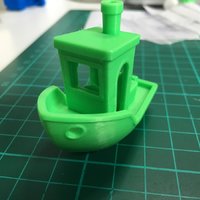

I tried a full-size benchy with flow reduced by additional 5%:

This time, there is way less of this candyfloss, looks like the too high flow was the culprit. For the first couple of test with the airbrush-nozzle, I am more than satisfied! And I'm eager to see what's possible with this type of nozzle!