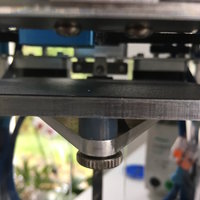

Silicon spacer as substitute for springs beneath the printbed

You probably know the vibration-damping feet for the DICE, already. They are casted out of durable silicone. This time, I did a substitute for the springs beneath the printbed

:

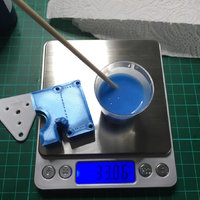

With the experience in using the cast for these feet, I improved the design of the cast a bit. Now, there is a lid and a baseplate, both removable. This should simplify the detaching of the silicone spacers after casting them. You can download the needed STL files here.

Lid and base are screwed tight with short M4 srews. In the baseplate are additional long M3 screws to make a hole in the casted parts.

Lid and baseplate are labeled, the font-side is the outer side when assembling the cast. In case there are no short screws available, one can shorten them by screwing a nut or two on the scews.

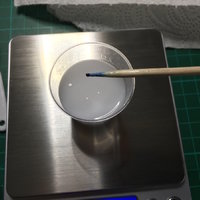

Then the silicone was mixed. The dying stuff I use is unbelievable strong. I mixed 20g (nearly a shot glas) of silicone with just a tip of a thoothpick of the Dye:

Don't get fooled: Only the very tip of the toothpick has dying stuff on it. The rest of the wood is still blue from the last time. This is enough to get a nice light blue color. If I had mixed less silicone, it would have become a much darker blue. Now it has the same color as the rest of the printed parts.

After mixing, I filled up the cast and beat it softly on the table to let the last airbubbles out. With the screwed tight lid the rest of the silicone squeezes out. This is intentional, because it signals, that the cast was filled up to the top. I cleaned of the silicone with kitchen paper and let it dry over night.

The next day, I removed all screws and both the lid and the baseplate. After wiggling the silicone a bit, it just came out of the cast. The three parts are mounted very fast. You can download the needed STL files here.